In recent years, the integration of generative AI into various industries has revolutionised traditional operational methodologies, ushering in an era of increased efficiency and enhanced creativity. For manufacturing and engineering firms looking to unlock quality at scale, AI is a key tool in improving efficiency and accuracy in your QMS.

How does generative AI work?

Generative AI operates by analysing a vast range of data inputs to create outputs based on what it has been given. It does this through a process called self-supervised learning, where it predicts subsequent elements (like the next word in a sentence) based on the patterns and contexts it has learned from the existing data.

Underneath the surface, these AI systems utilise deep learning, a branch of machine learning. Here, they work through neural networks with multiple layers, somewhat mimicking the human brain’s neural networks, to understand and find hidden patterns in the data.

When we look at its application in the real world, the capabilities of generative AI are applicable across most, if not all, industries. From its proficiency in data analysis to writing content and producing images, generative AI has a number of use cases that can improve the efficiency and accuracy of QMS platforms and their specific applications.

How AI empower QMS users

Implementing generative AI in your QMS platform creates a variety of benefits that fundamentally transform operational quality and efficiency. Here are the key avenues where AI makes a significant impact:

Analysing data at scale

Generative AI can quickly analyse enormous datasets, finding patterns and trends much more swiftly than a human could ever hope to. This means that users can rapidly gain deep insights from their data, helping them identify and address issues effectively.

Automation of repetitive tasks

Thanks to AI automation, time-consuming tasks such as data entry and information organisation become much quicker, drastically decreasing the time required to prepare for and undergo quality inspections. As workflows are made more efficient, teams are able to focus on more strategic, value-added activities.

Improved accuracy

AI drastically reduces the chance of human error by taking over repetitive tasks and applying algorithms to identify any irregularities in the data. This results in a much more accurate and reliable quality control process, giving users confidence in their data and outcomes.

Proactive issue resolution

AI’s ability to predict potential issues before they escalate is a game-changer, offering an avenue for preemptive solutions based on data trends and analytics, thereby avoiding costly setbacks and maintaining a high standard of quality.

How AI has been integrated into Singlepoint

Singlepoint now comes fully integrated with two powerful AI models, GPT-4 and DALL·E. Here are some examples of how you can utilise their capabilities in your system:

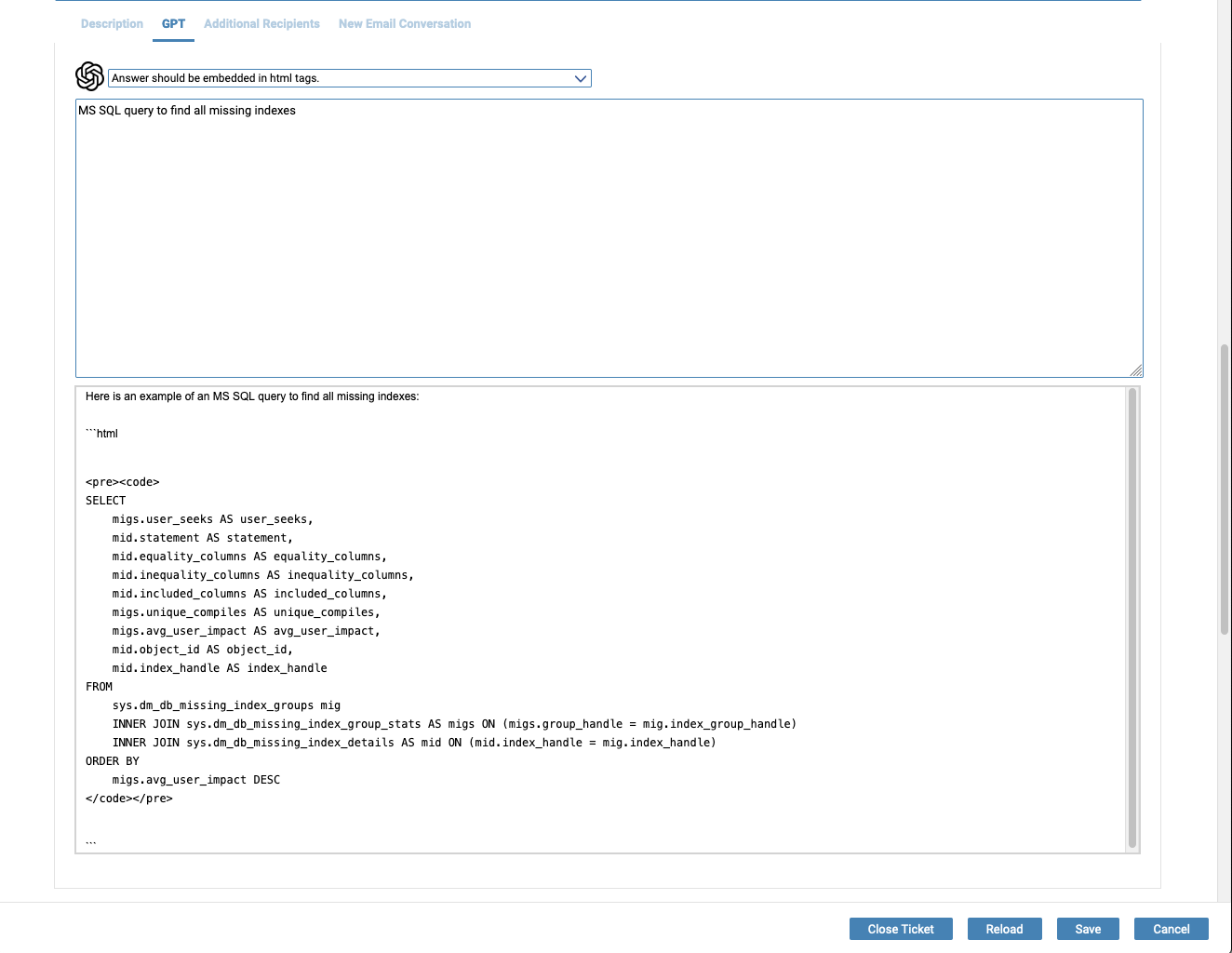

Leverage on-demand technical support:

Within Singlepoint, you can take advantage of GPT-4’s abilities to create and fine-tune code through simple text prompts. This feature empowers employees to swiftly modify existing workflows or establish new ones.

To provide a practical illustration, consider a scenario where a team needs to identify all missing indexes in a database. Through the interface, you can directly request GPT-4 to draft an MS SQL query tailored for this purpose, thereby facilitating a quick and accurate retrieval of the necessary information without delving deep into manual coding.

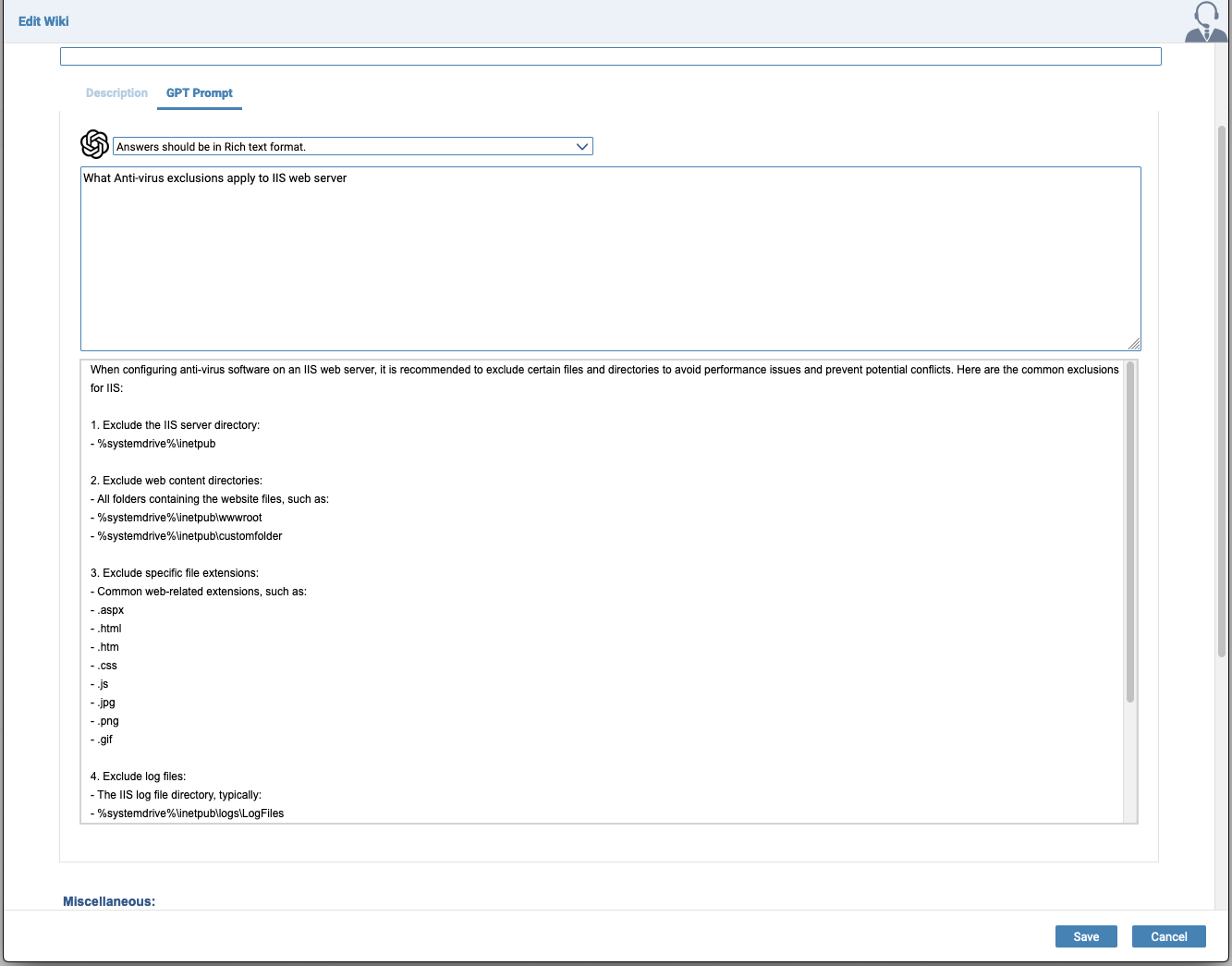

Create conversational interfaces

With GPT-4 at its core, Singlepoint facilitates the creation of conversational interfaces that are adept at handling user queries. These interfaces can rapidly sift through enormous data repositories to fetch exact answers, significantly enhancing the user experience.

Imagine a user seeking information housed within an expansive internal wiki or knowledge base. Through the conversational interface powered by GPT-4, they can pose questions and receive pinpoint answers derived from the extensive resources available, thereby streamlining the process of information retrieval and making knowledge accessibility swift and effortless.

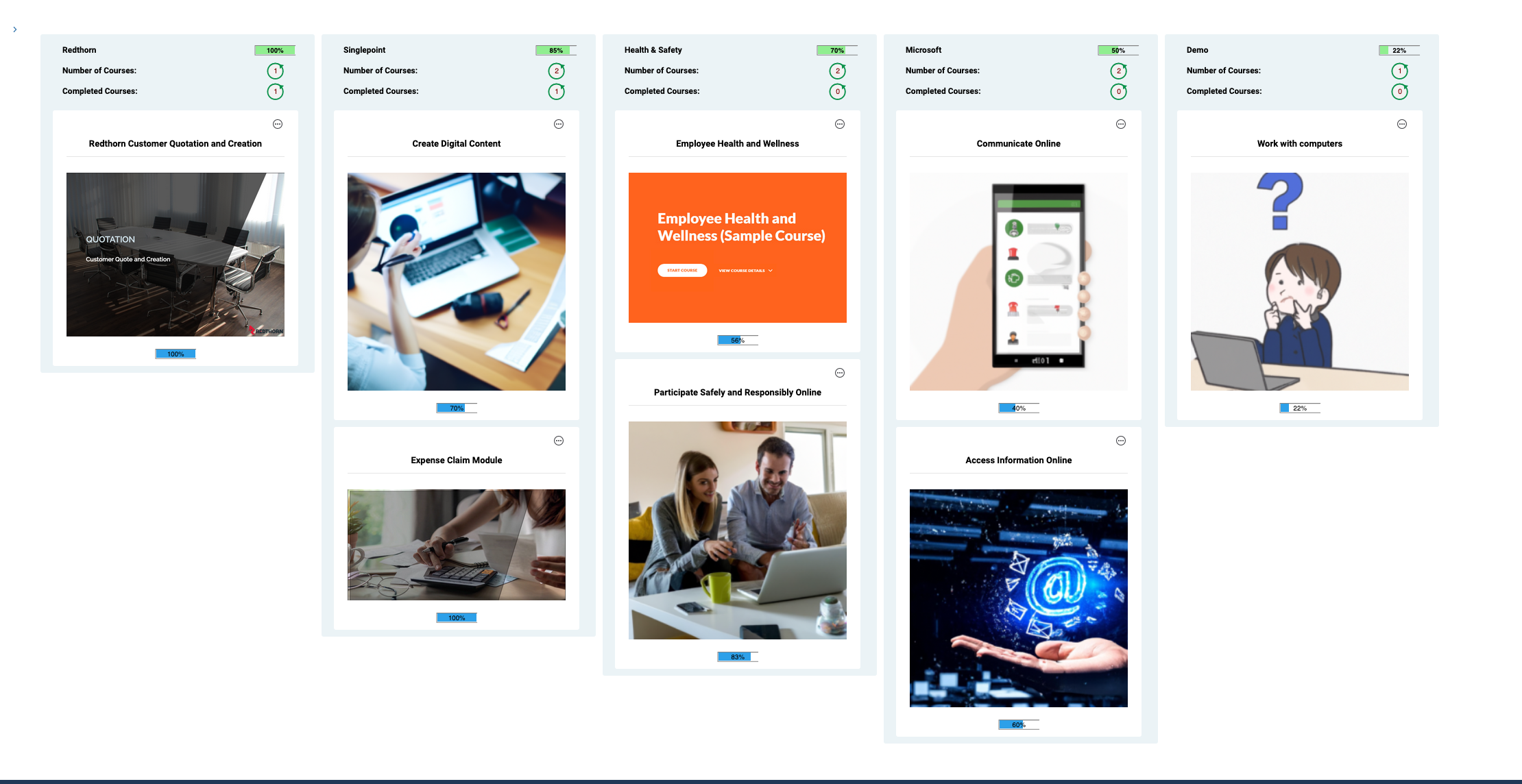

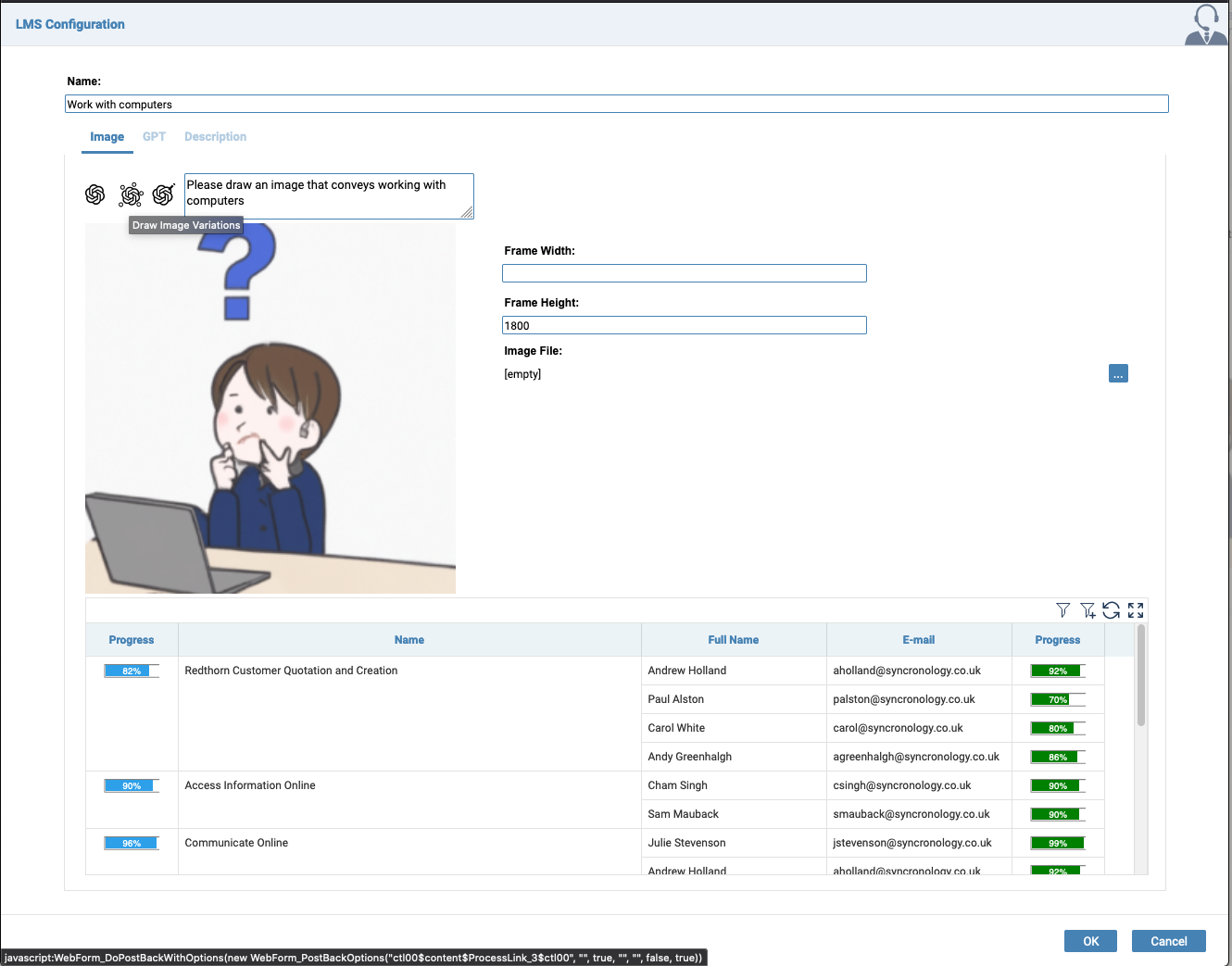

Enhance engagement with images

Singlepoint’s integration with DALL·E offers a revolutionary approach to creating dynamic and engaging visual content. This integration empowers users to craft images on the fly, enriching interfaces with visually appealing elements.

What makes this feature even more powerful is the ability to produce a range of variations on a single image concept, providing a versatile canvas for users to fine-tune visual elements.

How to integrate AI into existing quality management workflows

Step 1: Review your processes for opportunities

Begin by conducting a comprehensive review of your current QMS processes to identify areas ripe for AI integration. Consider aspects like data analysis, report generation and routine information-gathering tasks, then evaluate how AI can streamline these operations. This step should involve a cross-functional team with representatives from various departments to ensure a holistic assessment of opportunities.

Step 2: Train users to create effective prompts

Effective prompt creation is key to unlocking the full potential of AI. Equip your team with the skills to develop effective prompts for conversational AI interfaces, focusing on clarity and specificity. Workshops and hands-on training sessions can be a vital part of this phase, helping users understand the nuances of interacting with AI and encouraging them to experiment with different prompts to achieve the desired outcomes.

Step 3: Monitor outputs and apply continuous improvement

As you roll out AI-driven processes, it is vital to establish a system for monitoring performance and gathering data on the improvements achieved. Utilise this data to make informed decisions and to continuously refine the processes, fostering a culture of continuous improvement. As AI technology moves so swiftly, you should be conducting periodic reviews of your processes, looping back to Step 1 to understand your bottlenecks and the opportunities the latest models provide.

Explore the future with Singlepoint

If you’re looking to unlock the potential of AI within your QMS, the starting point might be a conversation to understand what is possible.

Book a demo today to explore how Singlepoint’s powerful AI integrations can help you improve efficiency and accuracy and empower users at scale.